Formwork and accessories

Formwork for the production of concrete is an additional assortment in the production of reinforced-concrete elements. The solutions we offer allow you to assemble moulds for concrete without damaging the casting surfaces.

Formwork for the production of concrete is an additional assortment in the production of reinforced-concrete slab elements. Formwork can also be used for the production of precast elements, where emphasis is placed on the long service life of the concrete casting surfaces (slabs, tilting tables).

The solutions we deliver use permanent magnets that allow for repeated use of the formwork without damaging the casting surfaces. Unlike carpentry formwork, there is no need to assemble the casting surfaces using fasteners such as screws or nails. At the same time, the design of our formwork makes work easier and shortens the time necessary for preparing the moulds.

The solutions we offer are based on each customer’s needs and requirements. The basic principles of formwork remain the same, and the final form is always custom-designed.

Classification

- magnetic sides

- magnetic sides carriers

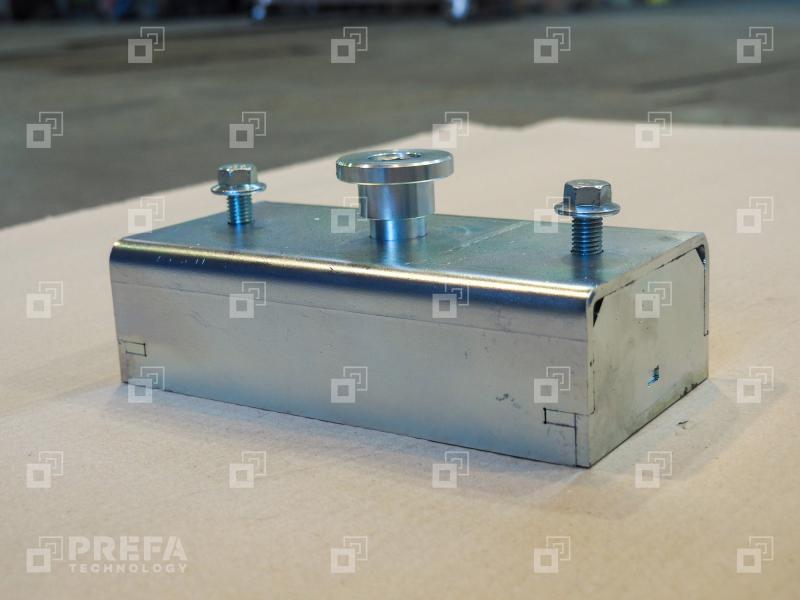

- magnetic boxes

- magnetic chamfers

- steel chamfers

- plastic chamfers

Magnetic sides

Magnetic sides are designed for the production of reinforced-concrete flat elements such as slabs, walls, hollow-core and sandwich slabs. Magnetic sides are typically used in moulds for flat elements(slabs, tilting tables).

Magnetic sides are a suitable solution for the serial production of flat elements with a constant profile height. The height of the sides is constant.

Magnetic sides are designed as a rigid weldment of steel sheets that form the side surfaces. The sides are complemented with integrated magnets, called magnetic boxes.

The magnets are affixed to the casting surface of the mould.

The number of magnetic boxes depends on the type of the element produced and the way the magnetic sides are used to suit the customer’s needs.

The sides can be designed flat or with chamfered edges, in single-sided or…