Moulds for the production of structural elements

Moulds for the production of structural elements are a good solution especially when producing reinforced-concrete precast elements such as smooth and cantilevered columns, girders, load bearers, and trusses. With the appropriate structural adjustment made to the mould, the shape of the produced precast element can be easily and efficiently changed.

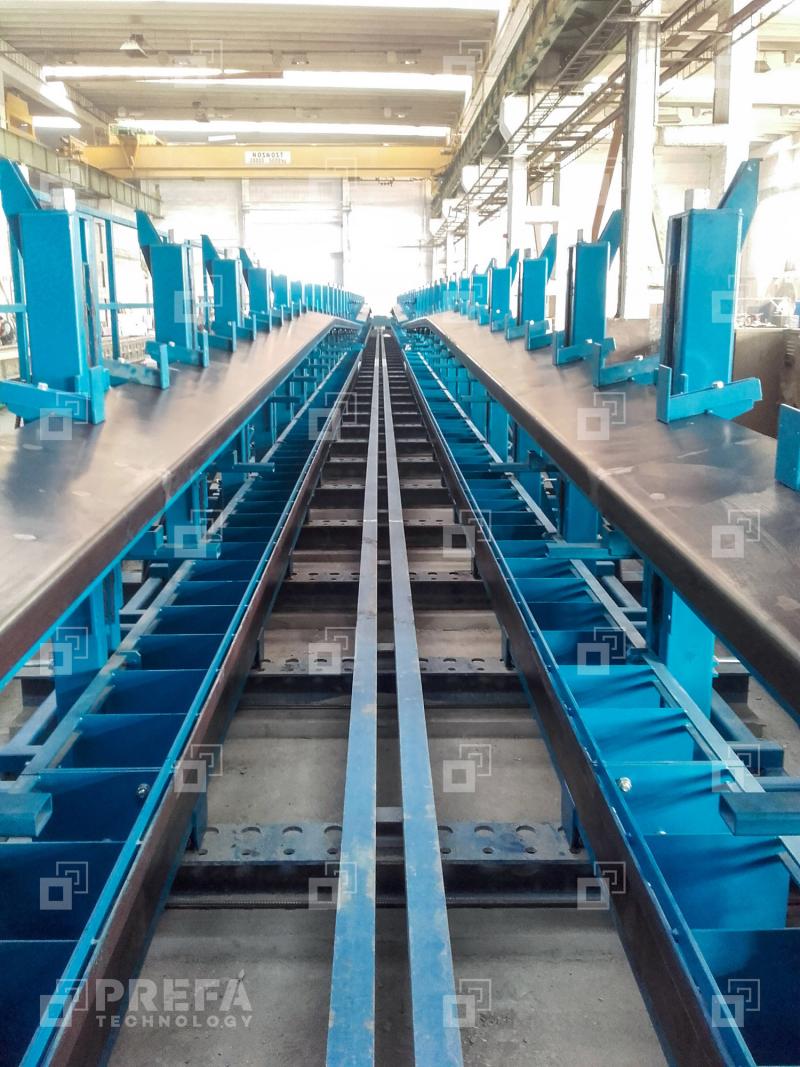

Moulds for the production of structural elements are made up of a steel frame, called a bed, which is anchored to the floor of the production hall and is rigid enough to allow for fixing sliding sides and the floor of the mould. The sides and floor of the mould are fitted with steel sheet metal or waterproof plywood. These materials make up the casting surface and the future external element of the produced precast element. The faces of the mould are made of waterproof plywood or steel sheet metal, depending on the type and number of elements produced. The faces are fixed, for example, using magnets – for more information, see Accessories for concrete production(proklik na související produkty) .

Depending on the total length of the mould, the sides are supplied as modular solutions with optional segment lengths (usually up to 6000 mm). The sides are moved mechanically or via a lifting device (lifting beam). Sides can be fitted with external vibrators or a hydraulic sliding mechanism.

Moulds for the production of structural elements are placed into the interiors of precast technology facilities.

To ensure the dimensional stability of the precast element throughout its entire cross-section, switching bars are placed in the upper part of the sides, ensuring a constant dimension in the upper and lower parts of the element mould during concreting.

Moulds for the production of structural elements (T/I-shaped girders and trusses) are universal in that they allow the user to change the shape and dimensions of the final reinforced-concrete element. When using extendable and tilting steel segments, called heads, the mould can be easily and efficiently readjusted. The mould with special segments allows the user to adjust to the required dimensions and the tilt of the upper…

Technical parameters of moulds for the production of structural elements

- casting surface flatness 1.5 mm/3000 mm

- mould length according to the customer’s requirements (6000–78 000 mm)

- sidewall module length approx. 6000 mm

Column, load bearer moulds

- element width

- up to 1000 mm

- element height (no extension)

- up to 800 mm

- element height (with an extension)

- up to 1200 mm

- parallel production of elements

- YES

Moulds for T/I-shaped girders and trusses

- upright thickness

- min 100 mm

- element height

- up to 2000 mm

- upper head width

- 350–700 mm

- upper head height

- 200–400 mm

- upper head tilt

- adjustable

- lower head height

- 350–400 mm

- upper head height

- 350–400 mm

- parallel production of elements

- YES